Sponge Drying Machine: A Game Changer In Dehydrating Fruits And Vegetables

Efficient moisture removal is vital in the food industry for quality retention as well as longevity and texture improvement. According to the latest trends, here too, we find sponge drying machines, which come in various models designed to meet specific needs: for example, potato sponge drying machines and vegetable sponge drying machines are shaking things up in the market by exploiting cutting-edge sponge roller dryer technology to improve the dehydrating process.

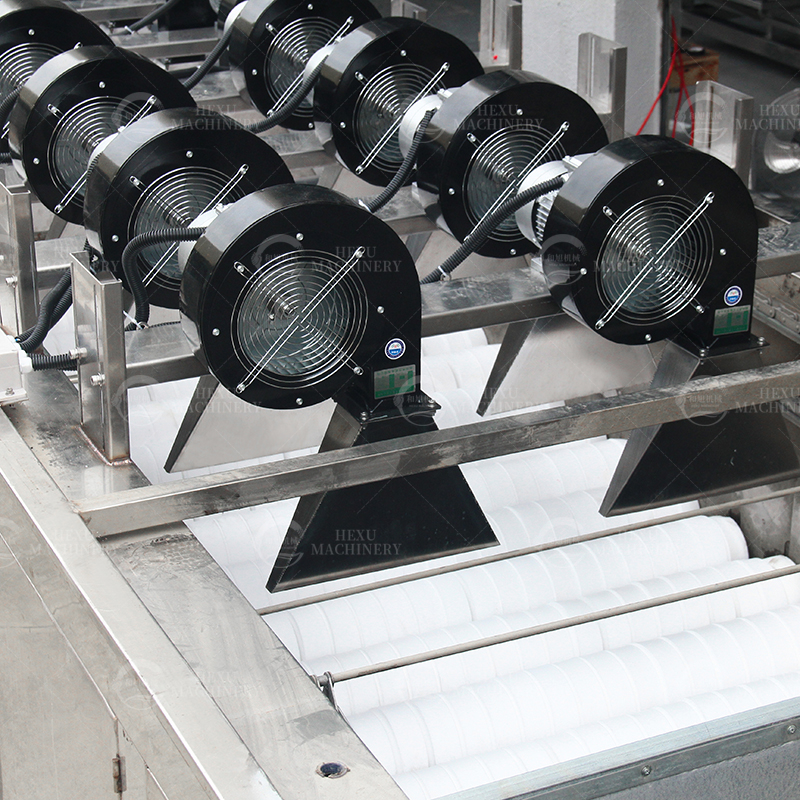

At the heart of these installations is the sponge dryer, which has the versatile ability to remove the surface moisture from foodstuffs in a gentle yet efficient manner. Unlike the traditional drying methods like air drying or centrifugal drying that can cause product damage or uneven drying, sponge dryers take advantage of soft, food-grade sponges to absorb water. Touch has a minimum point of contact, so as not to destroy delicate items, such as sliced potatoes or leafy vegetables, but still, the moisture is always the same.

For root vegetables such as potatoes, the potato sponge drying machine comes in handy. Potatoes are a key ingredient in many cuisines in the world and require efficient drying before processing downstream (like frying for chips or boiling and mashing for flakes, for example). These specialized vehicles with movable sponge rollers that provide uniform contact to the potatoes, extract surface moisture without damaging tubers. The result? Less oil is absorbed during frying, the texture is crunchier, and the cost of production is cheaper.

Vegetable sponge drying machines also vary to accommodate different vegetables such as carrots, celery, spinach, and bell pepper. These machines solve the problem of drying delicate foods with soft sponge pressure and temperature control. When they don't have excess heat, they maintain critical nutrients and bright colors, which equals the perfect ready-to-eat salads, frozen vegetable blends, and dehydrated snacks.

The sponge roller dryer, an essential part of such lines, ensures performance. It is fitted out with rotating sponge rollers that allow continuous operation, processing large quantities of vegetables without stopping. Constructed of food-safe, sturdy materials, the sponges are both replaceable and easily cleaned, allowing for sanitary compliance. Many models additionally feature PLC control systems, enabling staffers to fine-tune roller speed, pressure, and drying time to cater to product needs of everything from thin-sliced veggies to thicker potato blocks.

Apart from being efficient, drying machines for sponges are also environmentally friendly. Helping to cut carbon footprints in both the drying process and overall production costs, they reduce the energy-intensive nature of heat-based drying. Their precision is also a factor limiting waste; uniform drying ensures the product is properly dried while over-dehydration or waste is avoided.

To conclude, in summary, the sponge drying machines – including sponge dryers, potato sponge drying machines, vegetable sponge drying machines, and sponge roller dryers – are an essential part of today’s food processing industry. These systems combine product transport and handling with process functions for consistent and reliable performance with minimal operating costs and environmental impact. These modern technologies will increasingly be utilized to meet growing global demands for quality dehydrated foods, as the industry progresses.