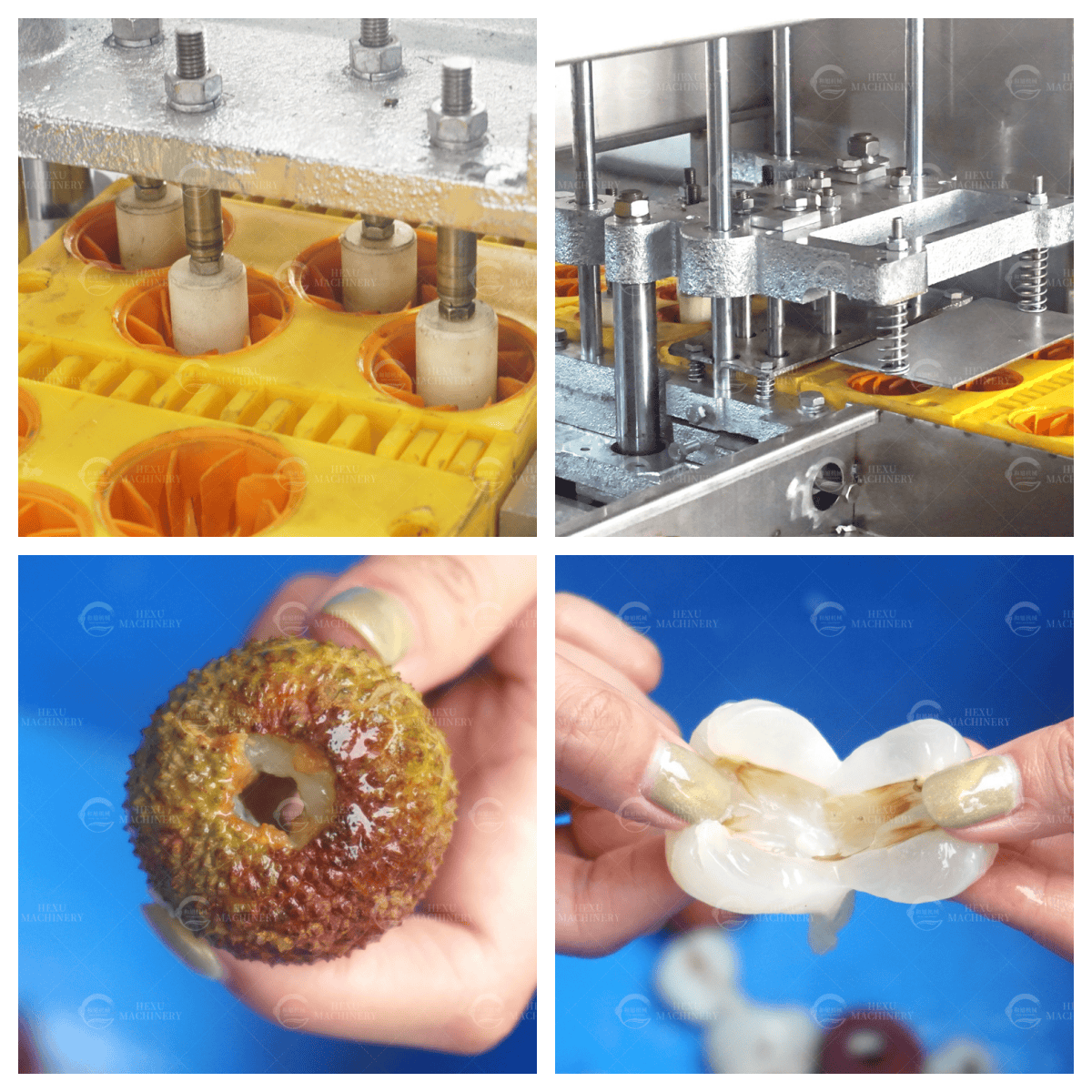

HexuMachinery’s fruit destoners employ precise pitting mechanisms—high-accuracy punches, cups and blades—to cleanly remove stones, pits, and seeds while retaining valuable fruit flesh. This pitting yields high recoveries,

which is key to product yield efficiency and profitability. The machines are engineered for multiple types of fruit or sizes, it allows for consistent pit removal whether for fresh pack pitted fruit or the further processing supply line.

Automation increases productivity. Including HexuMachinery’s pitters in a fruit processing line significantly increases the efficiency of producing fruit. Their systems normally have the ability to assist or be modular based on the

size settings, provide quick cycle times and easily integrate upstream with the fruit handling equipment (washing systems and sorting conveyors, etc.) and downstream with fruit processing equipment (slicers, dicers, fill machines, etc).

These systems have the ability to reduce levels of human handling, especially related to labor costs.

Hygienic design is critical. Constructed of food-grade stainless steel and designed for easy cleaning and sanitation (CIP/SIP where applicable), the HexuMachinery equipment is built to optimize your compliance with food safety

requirements (HACCP, GFSI, etc.). The durability and low maintenance of their industrial fruit destoners mean reliable investments.

Optimizing the fruit pitting process goes well beyond the main fruit pitting equipment you have; optimizing consistency and build quality starts by feeding fruits correctly, preparing the fruits correctly (for example, using graders or

sizers to ensure uniform sizing), and handling the fruits gently (without bruising them) to the pitting equipment to achieve your desired format parameters. Waste minimization is possible by ensuring an accurate pit ejection, reduced

fruit damage, and high pitting rate efficiencies. HexuMachinery ethnos is often integrated into fruit processing lines with other fruit processing pieces of equipment, literally creating a continuous equipment travel line.

For processors who are focused on yield maximization, quality of fruit product, and increased throughput in processing canned fruit, frozen fruit, dried fruit, or jam/pulp fruit products, HexuMachinery pitting devices can offer the accuracy,

consistency, and automation your process needs. Visit hexumachinery.com today and learn more about how we can offer technology to optimize your fruit process line.

Keywords: Fruit pitting machine, destoner, pit remover, fruit destoner, cherry pitter, olive pitter, peach pitter, apricot pitter, plum pitter, mango pitter, seed removal, stone removal, fruit processing equipment,

fruit processing machinery, fruit processing line, high-yield pitting, pit removal, pitting efficiency, fruit production efficiency, automation, food-grade stainless steel, hygienic design, food safety, reduced bruising,

reduced waste, consistent sizing, pit ejection, industrial fruit pitter, low maintenance, durability, washing system, sorting conveyor, slicer, dicer, grader, sizer, pitted fruit, canned fruit, frozen fruit, jam production.