After the fruits and vegetables are added to the feeding hopper, they are first crushed by the high-speed rotating hammer pieces through the crushing system. Then they are pressed under the push of the screw. The squeezed juice flows through the filter screen into the juice outlet pipe at the bottom, while the waste is discharged through the annular gap formed between the screw and the conical part for pressure regulation.

Machine Parameters:

Model: GZ-500 Juice Extracting Machine with Crusher

Dimension: 1100*500*1700mm

Voltage: 220V/380V/customized

Power: 3kw

Handling Capacity: 300-500kg/h

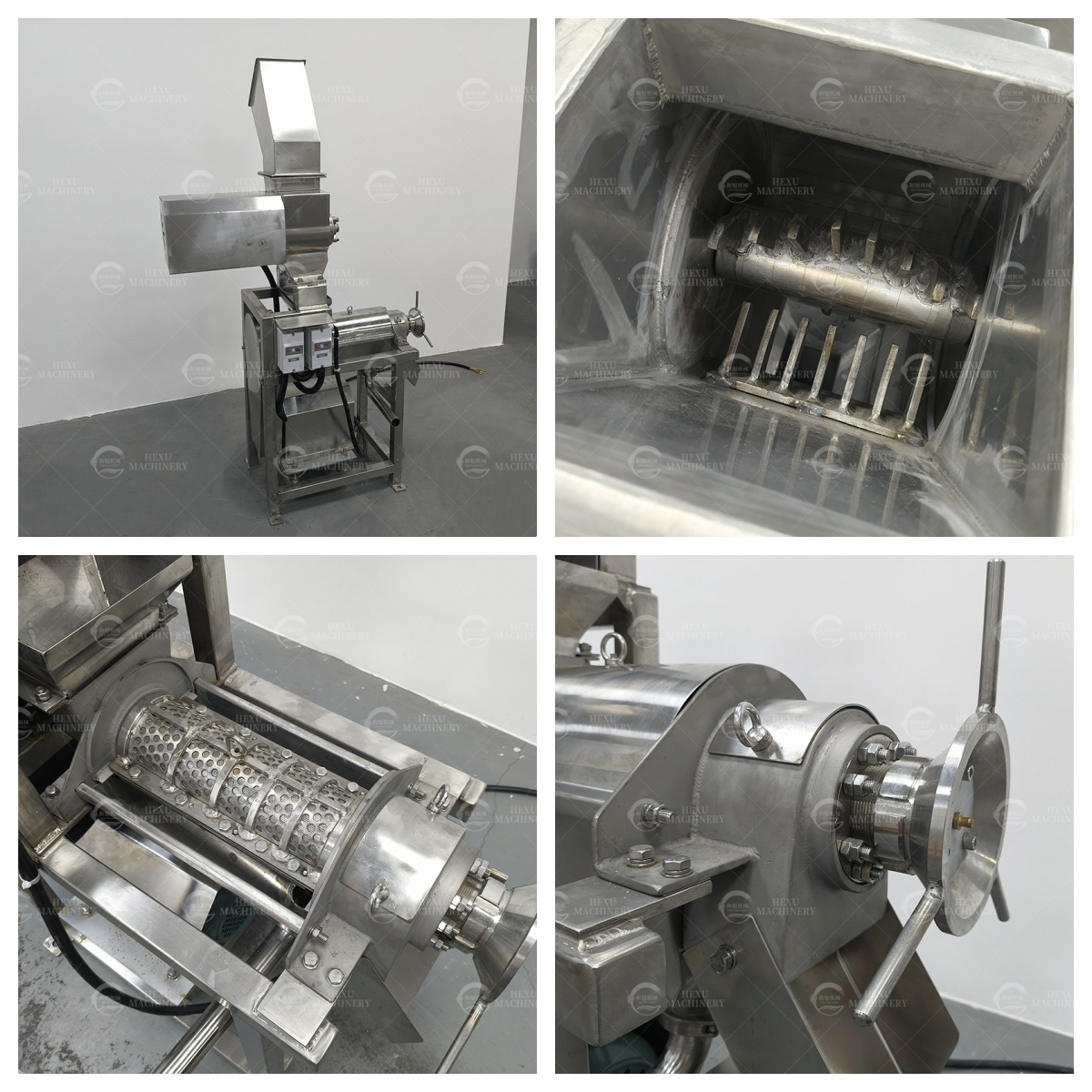

Machine Photos:

Machine Features:

※ The main component of the crushing system is the crushing device which is installed on the feeding hopper. During operation, the motor drives the main shaft to rotate for work. The materials are chopped by the high-speed rotating hammer pieces. Under the action of centrifugal force, the materials come out of the screen and enter the juicing system to improve the juicing effect.

※ The main component of the juicing system is the spiral. The screw gradually decreases along the direction of the waste residue outlet, while its bottom diameter gradually increases. When the materials are pushed forward by the screw, due to the reduction in the volume of the screw cavity, a squeezing effect is formed on the materials.

※ By changing the size of the annular space inside the machine, the resistance to residue discharge can be adjusted, and thus the residue discharge rate/juice discharge rate can be changed.

※ It can be combined with cleaning machines, dewatering machines and some other machines to form a fully automatic processing production line.

Finished Product Display:

Contact Information: